Blog

2026 Best Drum Tilters for Efficient Material Handling Solutions?

In the fast-paced world of material handling, efficiency is critical. The drum tilter has emerged as a vital tool in various industries. Dr. Emily Sanders, an expert in material handling systems, emphasizes, "A drum tilter can significantly reduce manual labor, improving safety and productivity." This statement highlights the value of drum tilters in modern operations.

Drum tilters play an essential role in safely handling heavy drums and containers. They streamline processes by tilting drums to facilitate pouring or transferring materials. This innovation minimizes spills and reduces the risk of accidents. However, not all drum tilters are created equal, and selecting the right model can be a challenge.

Companies must consider factors like load capacity, tilt angle, and durability. Often, businesses overlook these crucial aspects, leading to poor investment choices. Understanding the unique needs of each operation is essential. When implemented correctly, a well-chosen drum tilter can transform material handling, but careful evaluation is key to harnessing its full potential.

Overview of Drum Tilters and Their Importance in Material Handling

Drum tilters play a crucial role in material handling. These devices facilitate the safe and efficient movement of heavy drums. They can help prevent spills during transportation. By tilting the drums, users can easily access contents. This can save time and reduce manual effort.

In various industries, drum tilters are essential. They improve workflow and enhance worker safety. However, not all drum tilters are created equal. Some may lack the necessary stability. This can lead to accidents or injuries. It's important to assess quality before making a choice.

Additionally, proper training is vital for operators. Even the best equipment requires knowledgeable users. Misuse or neglect can lead to costly errors. Regular maintenance is needed to ensure longevity. If ignored, even top-grade tilters may fail when needed most. This should not be overlooked.

Key Features to Consider When Choosing a Drum Tilter

When looking for a drum tilter, several key features can enhance efficiency in material handling. First, consider the tilter's weight capacity. A robust model should handle heavy drums – typically between 55 to 100 gallons. Efficient models reduce strain on workers and improve safety. According to industry reports, businesses benefit from reductions in workplace injuries, leading to safer environments.

Another crucial feature is ease of operation. Many modern drum tilters offer ergonomic controls. This allows for smoother operation and less physical effort. A simple control mechanism should promote speed without sacrificing safety. Additionally, tilt angles that range between 30 to 45 degrees are often optimal. This range ensures that materials flow out effectively without spillage.

Tips: Regular maintenance is vital for longevity. Inspect moving parts often. Training operators on correct usage can minimize errors. Always check for signs of wear before heavy use. While many choose automatic models, manual options remain reliable. They might require more effort but can be more cost-effective in some scenarios. Efficiency isn't just about the equipment. It's also about the operator's knowledge and skill.

Top Brands and Models of Drum Tilters for 2026

When considering drum tilters for efficient material handling solutions, it's crucial to evaluate top brands and models that can support your needs in 2026. These machines significantly enhance workflow by aiding in the safe and efficient handling of heavy drums. They help reduce strain on workers, minimizing injury risks. Moreover, they contribute to a more organized workspace.

**Tip:** Always check for the capacity of the drum tilters. Ensure they meet your operational demands for the types of materials you handle. Many models vary in weight capacity and size. It’s essential to choose one that aligns well with your specific needs.

Ergonomics play a vital role in drum tilter selection. A well-designed tilter can prevent repetitive strain injuries. However, many users overlook this aspect. Failing to pay attention can lead to discomfort and inefficiency.

**Tip:** Consider models with adjustable heights. This feature can provide flexibility. It allows different operators to use the equipment comfortably. Small adjustments can lead to significant improvements in daily operations.

2026 Best Drum Tilters for Efficient Material Handling Solutions

This chart presents key features of the best drum tilters for 2026, including weight capacity, height adjustment, tilt angle, price, and expected durability in years. These metrics are crucial for selecting the most efficient material handling solution.

Comparative Analysis of Drum Tilter Efficiency and Productivity

In the world of material handling, drum tilters play a vital role. They help lift and tilt heavy drums for easier pouring and transfer of contents. Efficiency is key in operations. A well-designed drum tilter can reduce the time it takes to handle materials. However, not all drum tilters offer the same level of performance.

Some drum tilters struggle with stability. Operating an unstable tilter can lead to spills and wasted resources. This not only impacts productivity but also increases safety risks. Workers may feel anxious using equipment that doesn’t perform reliably. A thorough comparison of different models reveals nuances in productivity. Design, weight capacity, and ease of use often vary significantly.

Efficiency is not purely about speed. It also involves worker comfort and safety. A tilter that strains user muscles can decrease overall productivity. While some products are marketed as efficient, real-world testing often uncovers flaws. Gathering feedback from operators offers insights into what improvements are necessary. These reflections are crucial for enhancing overall drum tilter performance.

Safety Considerations and Best Practices for Using Drum Tilters

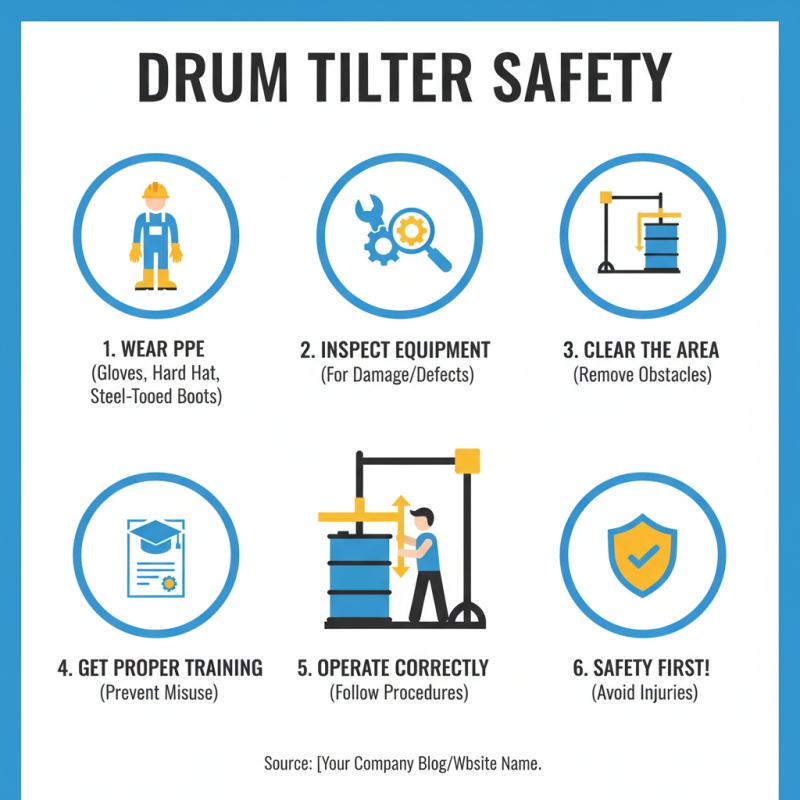

When using drum tilters, safety is paramount. Operators should always wear appropriate personal protective equipment (PPE). This includes gloves, hard hats, and steel-toed boots. Before operating the tilter, inspect it for any damages or defects. Ensure the area is clear of obstacles to prevent accidents. It's also crucial to have proper training. Inadequate training can lead to misuse and potential injuries.

Always follow the manufacturer's guidelines for weight limits. Overloading a tilter can cause mechanical failures or tip-overs. Operators should maintain a steady pace while tilting. Quick, jerky movements may lead to spills or accidents. Keeping a safe distance from others while operating the equipment is wise.

Regular maintenance is vital for safety. Check hydraulic systems for leaks and ensure all components function properly. If you notice any issues, address them immediately. Ignoring small problems can lead to larger failures. Remember, safety protocols are there for a reason. They should never be overlooked or taken lightly. Reflect on the importance of these practices, as they can save lives and prevent injuries.

Related Posts

-

How to Properly Handle Drums for Safe and Efficient Transport

-

Top 10 Drum Lifting Equipment Options for Safe and Efficient Handling

-

Top 10 Material Handling Solutions Tips for Efficient Operations

-

Top Material Handling Products to Boost Efficiency in 2025

-

What is Drum Handling and How to Safely Manage Drums in Your Workplace

-

10 Essential Tips for Choosing the Right Industrial Lifting Equipment