Blog

Top 10 Drum Lifting Equipment Options for Safe and Efficient Handling

When it comes to safely and efficiently handling industrial drums, choosing the right drum lifting equipment is crucial. With various types of applications across manufacturing, warehousing, and construction environments, the demand for high-quality lifting solutions has never been greater. Proper selection and usage of drum lifting equipment not only enhance operational productivity but also significantly reduce the risks of workplace injuries, making safety a top priority for employers and employees alike.

In this guide, we will explore the top 10 drum lifting equipment options available on the market today. From ergonomic designs that ensure user comfort to innovative mechanisms that optimize load stability, each option serves a unique purpose in facilitating the effective handling of heavy drums. Understanding these diverse tools is essential for organizations aiming to improve their material handling processes while adhering to safety guidelines. Whether you are looking to upgrade your existing equipment or just starting to explore your options, this overview will provide valuable insights into the most effective solutions for your drum lifting needs.

Overview of Drum Lifting Equipment Types and Their Applications

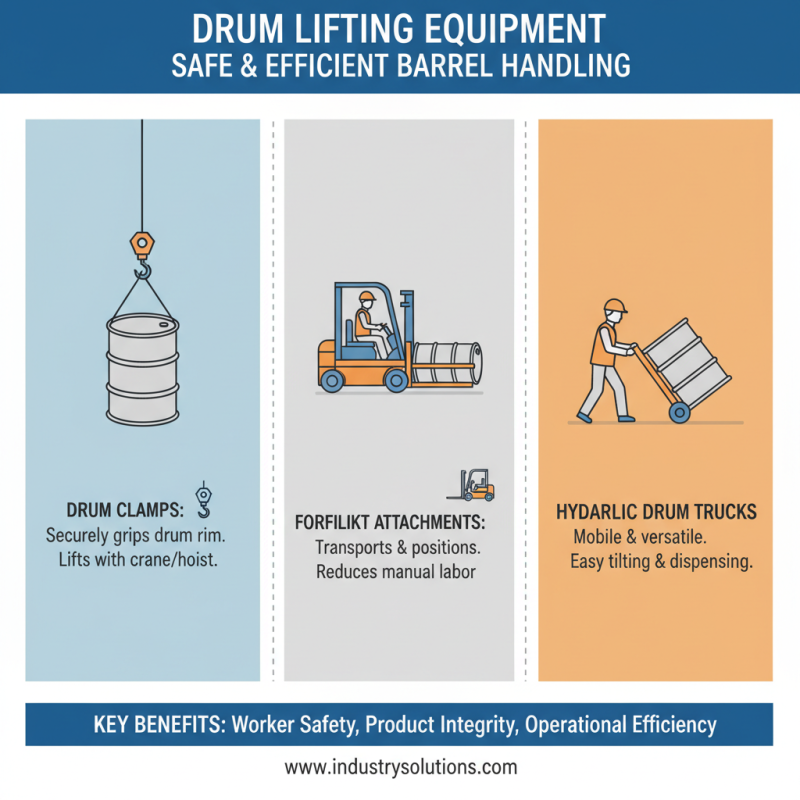

Drum lifting equipment is essential in various industries for the safe and efficient handling of heavy barrels. These tools are designed to tackle the specific challenges associated with moving and positioning drums, ensuring both the safety of workers and the integrity of the contents. One common type is the drum clamp, which securely grips the top rim of the drum, making it easy to lift with a crane or hoist. These clamps are versatile and can be used in manufacturing plants, warehouses, and construction sites where drums need to be moved frequently.

Another popular option is the drum dolly, a wheeled platform that allows for easy transportation of drums across flat surfaces. This equipment is particularly beneficial in facilities with limited space, as it minimizes the risk of accidents or spills during movement. Drum lifters are also available, which enable operators to pick up drums directly from the ground or pallet and place them onto higher elevations, such as shelves or containers. Each type of drum lifting equipment is designed with specific applications in mind, catering to different requirements in terms of load capacity, mobility, and environment, thereby enhancing workplace efficiency and safety standards.

Key Features to Consider When Choosing Drum Lifting Equipment

When selecting drum lifting equipment, safety and efficiency should be prioritized. One of the key features to consider is the weight capacity of the equipment. It’s crucial to assess the maximum weight the lifter can handle, as this ensures it can safely lift drums without risking structural integrity or operator safety. Additionally, consider the material and build quality of the lifting device. Durable materials such as high-grade steel or heavy-duty composites can enhance longevity and reliability, making them suitable for rigorous industrial environments.

Another essential feature is the lifting mechanism itself. Options include manual, hydraulic, and electric systems, each catering to different operational needs. For instance, hydraulic lifts provide significant power with minimal effort, which can be beneficial for frequent lifting tasks. Moreover, ease of use and ergonomics should not be overlooked; a design that minimizes physical strain on the operator can lead to increased productivity and reduced injury rates. Other considerations include the equipment's mobility, adaptability for various drum sizes, and compatibility with existing equipment. By carefully evaluating these features, businesses can choose the most effective drum lifting solutions to enhance their operational workflows.

Top 10 Drum Lifting Equipment Options

Comparison of Manual vs. Automatic Drum Lifting Solutions

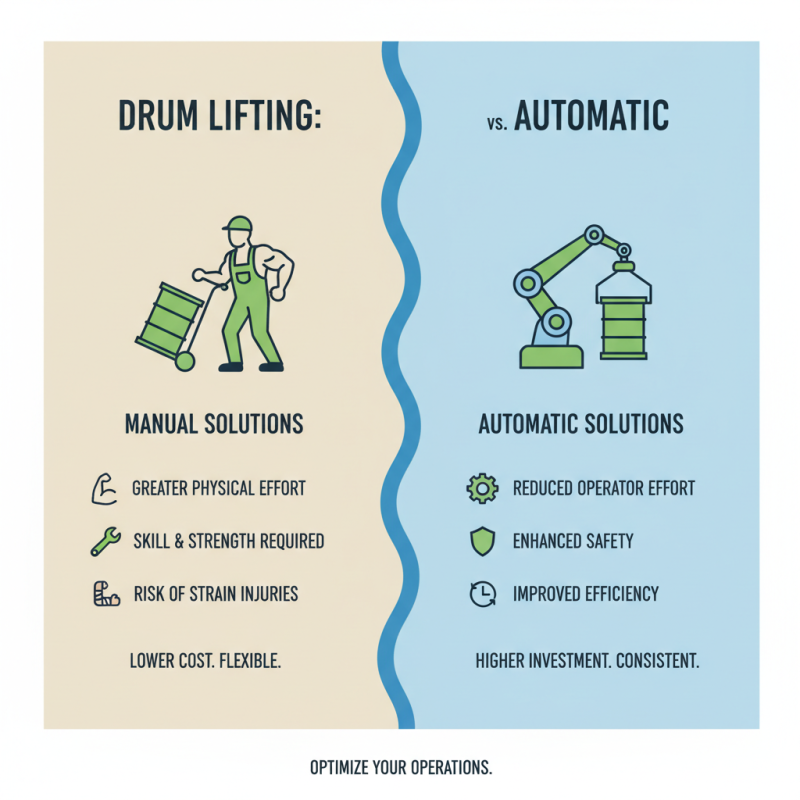

When it comes to drum lifting equipment, organizations often face the decision between manual and automatic solutions. Manual drum lifters typically involve a greater physical effort from the operator. These solutions, while economical, require a significant level of skill and strength to ensure safety while moving heavy drums. Operators must be trained to handle equipment properly and maintain vigilance to prevent accidents. Manual systems may offer flexibility in operation, but they also carry the risk of strain injuries and inefficiencies in environments where many lifts are required.

On the other hand, automatic drum lifting solutions present a different array of advantages focused on efficiency and safety. These systems reduce the physical demands placed on operators, minimizing the risk of injury through automation. With features such as powered lifts and streamlined controls, automatic systems can enhance productivity by allowing for quicker operation, especially in high-volume scenarios. Furthermore, many automatic options come equipped with safety mechanisms that ensure secure handling, reducing the likelihood of accidents. As industries continue to prioritize safety and efficiency, the shift towards automated lifting solutions is becoming increasingly prevalent.

Safety Standards and Regulations for Drum Handling Equipment

When handling drums, adherence to safety standards and regulations is crucial to prevent accidents and ensure efficiency in operations. The Occupational Safety and Health Administration (OSHA) outlines specific guidelines regarding drum handling equipment, emphasizing the need for appropriate safety features such as overload protection and secure lifting attachments. According to the National Institute for Occupational Safety and Health (NIOSH), ergonomic considerations are also essential; improper handling can lead to musculoskeletal disorders, with over 300,000 cases reported annually in the United States due to repetitive strain and awkward postures associated with drum handling.

In addition to OSHA standards, the American National Standards Institute (ANSI) provides metrics for evaluating the integrity and performance of drum lifting equipment. For instance, it is advised that lifting devices should be rated for at least twice the maximum load to ensure safety during operations. Recent studies have shown that companies implementing such safety measures saw an 18% reduction in workplace injuries related to drum handling. Furthermore, regular inspections and maintenance of equipment not only comply with regulatory requirements but also enhance operational efficiency, leading to improved productivity and reduced downtime in the workplace.

Maintenance Tips for Ensuring Equipment Longevity and Performance

Proper maintenance is essential for ensuring the longevity and performance of drum lifting equipment. Regular inspections should be conducted to check for signs of wear and tear, as well as to ensure that all components are functioning correctly. This includes examining hooks, chains, and slings for any damage or deformation that could compromise safety. Lubrication of moving parts is also crucial; it helps reduce friction and wear, ensuring smooth operation. Keeping the equipment clean and free from debris contributes to its efficiency and prevents potential hazards during use.

In addition to regular inspections, adhering to the manufacturer's guidelines for maintenance is vital. This may include periodic testing of load capacity and functionality to confirm that the equipment meets safety standards. Operators should be trained in proper usage techniques to prevent misuse, which can lead to premature wear or accidental damage. Creating a maintenance schedule can help ensure that these tasks are routinely performed, thereby extending the lifespan of the equipment and enhancing its reliability. By prioritizing maintenance, organizations can safeguard not only their equipment but also their workforce's safety during drum handling operations.

Top 10 Drum Lifting Equipment Options for Safe and Efficient Handling

| Equipment Type | Weight Capacity (lbs) | Material | Features | Maintenance Tips |

|---|---|---|---|---|

| Drum Lifter | 2,000 | Steel | Forklift Compatible | Regularly inspect for wear and tear. |

| Drum Trolley | 1,500 | Aluminum | Portable Design | Clean wheels and check brakes regularly. |

| Electric Drum Handler | 1,000 | Electric Motor | Easy Operation | Charge battery regularly for optimal performance. |

| Manual Drum Pump | N/A | Plastic | Hand Operated | Lubricate the pump regularly. |

| Drum Grab | 1,800 | Steel | Secure Grip | Check grip for wear before use. |

| Cradle Lifter | 2,200 | Steel | Stable Base | Inspect slings and hooks regularly. |

| Drum Rack | 3,000 | Metal | Space Saving | Regularly check for rust and corrosion. |

| Drum Dolly | 1,200 | Steel/Plastic | Easy Mobility | Keep tires inflated and check for damage. |

| Hydraulic Drum Lifter | 2,500 | Steel | Hydraulic Operation | Check hydraulic fluid levels regularly. |

| Adjustable Drum Clamp | 1,600 | Aluminum | Versatile Fit | Inspect for wear on adjustment knobs. |

Related Posts

-

Why Investing in Quality Drum Lifting Equipment Saves Time and Reduces Risks

-

How to Properly Handle Drums for Safe and Efficient Transport

-

Top Material Handling Products to Boost Efficiency in 2025

-

Top 5 Innovative Material Handling Solutions to Enhance Your Warehouse Efficiency

-

10 Essential Tips for Choosing the Right Industrial Lifting Equipment

-

Top 10 Best Material Hoists for Efficient Construction Projects in 2023