Blog

Essential Tips for Choosing Stainless Steel Wire Mesh?

Choosing the right stainless steel wire mesh is crucial for various applications. It’s more than just a filter or barrier. John Smith, a renowned expert in the stainless steel wire mesh industry, once stated, “The right choice can significantly enhance efficiency and durability.” This highlights the importance of understanding the specific needs of your project.

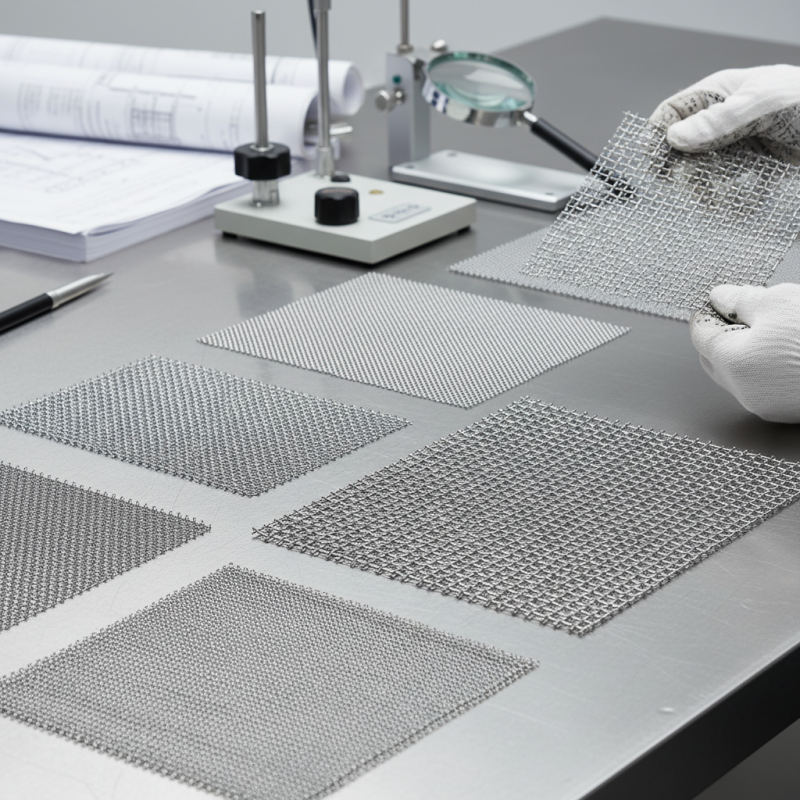

When selecting stainless steel wire mesh, consider factors like mesh size, wire diameter, and material grade. These elements directly impact strength and lifespan. You might think that all mesh is the same, but that’s misleading. Different applications require unique specifications.

It’s easy to overlook the finer details. Sometimes, buyers focus too much on price. This approach can lead to poor choices that affect performance. Think of the long-term implications of your selection. Quality should never be compromised for cost.

Factors to Consider When Selecting Stainless Steel Wire Mesh

When selecting stainless steel wire mesh, several factors are crucial. One of the primary considerations is the wire diameter. Thicker wires provide greater strength and durability, while thinner wires offer better flexibility. According to industry reports, a wire diameter of 0.25 mm is common for general applications, while heavy-duty setups may require diameters of 0.5 mm or more.

Next, the mesh opening size is important. Smaller openings can filter out fine particles, making them ideal for applications like filtration. Meanwhile, larger openings allow for airflow and light penetration, suitable for architectural uses. Research highlights that a mesh opening of 2 mm typically balances strength and functionality. However, measuring accurately can be tricky; slight discrepancies might lead to ineffective results.

Finally, consider the grade of stainless steel. Common grades like 304 and 316 offer different levels of corrosion resistance. While 304 is suitable for most environments, 316 is better for harsh conditions. Yet understanding the specific requirements can be daunting. Many users overlook the long-term implications of their choice, potentially leading to costly replacements. Inadequate attention to these factors may hinder performance in their intended applications.

Factors to Consider When Selecting Stainless Steel Wire Mesh

Understanding Different Grades of Stainless Steel for Wire Mesh

When selecting stainless steel wire mesh, understanding the different grades of stainless steel is crucial. Stainless steel grades vary in composition and characteristics. Common grades include 304 and 316. Grade 304 is versatile and resistant to corrosion, making it suitable for many applications. However, it may not perform well in highly acidic environments.

On the other hand, grade 316 offers better resistance to corrosion, especially against saltwater. This makes it ideal for marine applications. But, it’s often more expensive. The choice between these grades requires careful consideration of your specific needs. Think about the environment where the mesh will be used. It’s not just about picking a grade; it’s about understanding how it will perform over time.

Choosing the right wire mesh can feel overwhelming. Options are endless, and each has pros and cons. Reflect on your project’s requirements and potential challenges. Sometimes, trial and error may lead to the best decision. Don't hesitate to consult experts for advice, as their insights can be invaluable.

Mesh Size and Wire Diameter: How They Impact Performance

Choosing the right stainless steel wire mesh involves understanding mesh size and wire diameter. Mesh size refers to the number of openings per linear inch. A finer mesh size means smaller openings. Larger openings allow for better airflow but less filtration. Think about your specific needs. Know what you want to achieve.

Wire diameter also plays a significant role. Thicker wires are sturdier and can handle more tension. However, they also restrict flow more than thinner wires. This balance is crucial for performance.

Tips: Always consider your project's requirements. For applications with high pressure or temperature, opt for thicker wire. When dealing with finer particles or need for filtration, select a finer mesh. Reflect on how these choices affect your end goals. A small mistake can lead to bigger issues down the line.

Applications of Stainless Steel Wire Mesh in Industry and Home

Stainless steel wire mesh finds its utility across various sectors. In the food and beverage industry, it plays a critical role. Its resistance to rust and contamination ensures safe food processing. According to a report by the International Food Safety Network, over 30% of foodborne illnesses stem from improper handling. This highlights the importance of using stainless steel materials in production environments.

In residential settings, stainless steel wire mesh is often used for safety and aesthetic reasons. Homeowners utilize it for window screens, pet enclosures, and decorative pieces. It does not corrode easily, making it ideal for humid areas. Statistics show that the demand for durable home materials has risen by 20% in recent years. However, it's essential to choose the right mesh size. A mesh that is too large may not provide adequate safety for small pets.

Some installations may pose challenges. Incorrect sizing can lead to inefficiency, while poor quality can compromise safety. A study by the Wire Mesh Association indicates that a significant number of users regret their choices due to inadequate research. Take time to assess your needs before finalizing a purchase. A well-informed choice can prevent costly mistakes later on.

Maintenance Tips for Long-lasting Stainless Steel Wire Mesh

When it comes to maintaining stainless steel wire mesh, a few key practices can enhance its longevity. Regular cleaning is essential. Use warm soapy water followed by a rinse. In tough cases, a gentle abrasive may be necessary. Avoid harsh chemicals. They can harm the surface finish. At times, rust can appear, which is frustrating. Promptly address it with a mild scrub to prevent it from spreading.

Another important aspect is proper storage. If the mesh is not in use, keep it in a dry place. Moisture can lead to corrosion over time. Regular inspections are crucial. Look for any signs of damage or wear. If you notice any issues, it’s better to replace the damaged sections immediately.

Consider how the mesh interacts with its environment. In salty or acidic settings, the wear may accelerate. Regularly check and adapt your cleaning routine based on these factors. Each setting presents unique challenges. Being vigilant holds the key to preserving your stainless steel wire mesh for years to come.