Blog

Top Lifting Gear Trends for 2025 You Need to Know About Now

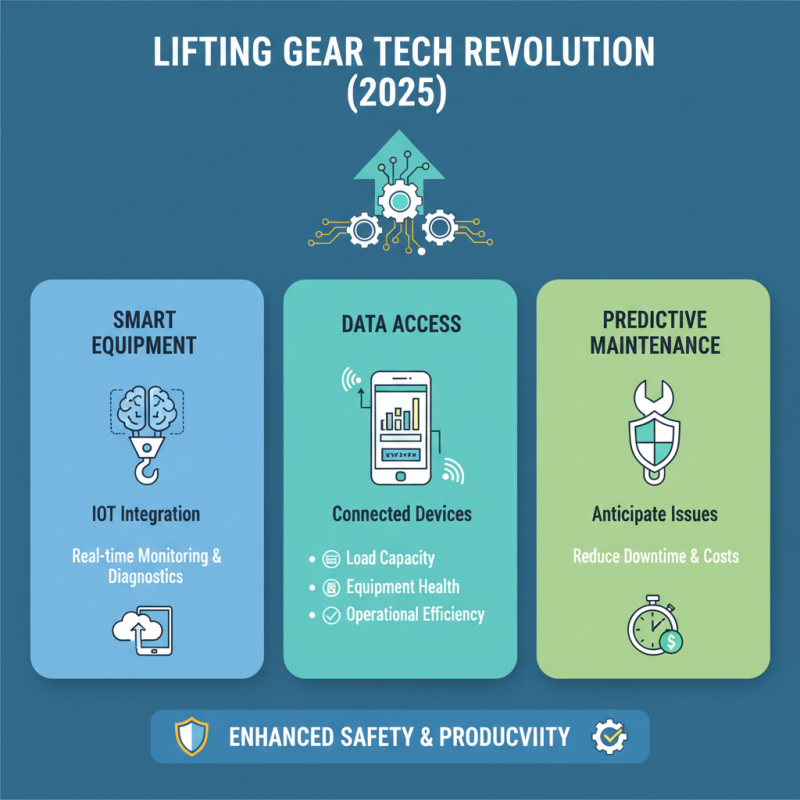

As we look ahead to 2025, the lifting gear industry is poised for significant transformation driven by advancements in technology, safety standards, and sustainability practices. Operators and engineers across various sectors will find it crucial to stay informed about these evolving trends, which are set to reshape how lifting operations are performed. The integration of smart technologies, such as IoT and AI, is revolutionizing traditional lifting gear by enhancing efficiency and providing real-time monitoring capabilities, thereby improving job site safety and operational performance.

Additionally, the ongoing emphasis on sustainability is influencing the design and production of lifting gear, prompting manufacturers to adopt eco-friendly materials and methods. This shift not only responds to regulatory pressures but also aligns with broader corporate responsibility initiatives within the industry. As we explore the key trends that will define lifting gear in the coming years, it becomes evident that staying ahead in this dynamic environment is essential for businesses aiming to enhance their operational capabilities and ensure the highest levels of safety in their lifting applications. Understanding these trends is not just an option but a necessity for professionals committed to leveraging lifting gear innovations for future success.

Emerging Technologies in Lifting Gear: A 2025 Overview

The lifting gear industry is on the brink of a technological revolution as we approach 2025. One of the most notable trends is the integration of smart technologies into lifting equipment. This includes the use of Internet of Things (IoT) capabilities that allow for real-time monitoring and diagnostics. Operators can now access data related to load capacity, equipment health, and operational efficiency through connected devices, which enhances safety and productivity on job sites. With predictive maintenance becoming the norm, potential issues can be identified before they escalate into costly failures.

Another emerging technology is the advancement of lightweight and high-strength materials in lifting gear production. As industries demand more efficient and versatile equipment, manufacturers are exploring the use of composite materials and innovative metal alloys. These materials not only reduce the weight of lifting gear but also improve the overall strength and durability, ensuring that equipment can handle demanding applications while minimizing wear and tear. Furthermore, advancements in robotic technologies are also making their way into lifting operations, allowing for automation of heavy lifting tasks, which can further enhance workplace safety and efficiency.

Sustainability Trends Influencing Lifting Equipment Design

The lifting equipment industry is undergoing a significant transformation, largely driven by a growing emphasis on sustainability. As companies align with global initiatives aimed at reducing carbon footprints, the design and manufacturing of lifting gear are becoming more environmentally friendly. Innovations in materials, such as the use of recycled and bio-based composites, are becoming essential. These materials not only reduce reliance on traditional resources but also enhance the longevity and performance of lifting equipment, lowering maintenance costs and environmental impact over time.

Additionally, energy efficiency is a critical trend influencing the development of modern lifting equipment. The integration of advanced technologies, such as electric and hybrid systems, is helping to mitigate greenhouse gas emissions associated with diesel-powered machinery. Smart technologies, including IoT sensors, are being incorporated to monitor energy usage and optimize operations, allowing companies to operate more sustainably. As businesses prioritize eco-friendly practices, the shift toward sustainable lifting equipment design is expected to gain momentum, ultimately reshaping industry standards and customer expectations.

Top Lifting Gear Trends for 2025

This chart illustrates the projected growth of key sustainability trends influencing lifting equipment design by 2025. The data considers increasing demand for eco-friendly materials, automation, and energy efficiency in the lifting gear market.

Advanced Safety Features Revolutionizing Lifting Operations

In the evolving landscape of lifting operations, advanced safety features are at the forefront of enhancing operational efficiency and worker protection. As we move toward 2025, technology continues to play a pivotal role in revolutionizing the lifting gear industry. Innovations such as integrated load monitoring systems and real-time safety alerts are becoming standard, ensuring that operators can work with precise, actionable information at their fingertips. These advancements not only help in preventing accidents but also increase productivity by providing insights that allow for better planning and execution of lifting tasks.

When implementing new lifting gear, it's essential to prioritize safety features. **Tip 1**: Regular training on the latest equipment and safety protocols significantly reduces the risk of accidents. Ensure all team members are well-versed in utilizing safety features effectively. **Tip 2**: Conduct routine inspections and maintenance checks on lifting devices to confirm that safety mechanisms, such as emergency stops and overload protection, are functioning correctly. Keeping up with these practices not only adheres to safety regulations but also fosters a culture of safety within the workplace.

As we approach 2025, the integration of AI and IoT in lifting gear will further enhance safety protocols. These technologies can facilitate predictive maintenance, thereby identifying potential hazards before they lead to failures. **Tip 3**: Embrace technology by adopting systems that provide data-driven insights into lifting operations. This can empower firms to make informed decisions, ultimately leading to safer and more efficient lifting practices. By staying ahead of these trends, businesses can ensure a secure environment for their operations and workforce.

Top Lifting Gear Trends for 2025 You Need to Know About Now - Advanced Safety Features Revolutionizing Lifting Operations

| Trend | Description | Expected Impact | Implementation Timeline |

|---|---|---|---|

| Smart Load Monitoring | Integration of IoT devices for real-time load monitoring. | Increases safety and efficiency by preventing overloads. | 2023-2025 |

| Automated Lifting Systems | Use of robotics and automation for lifting tasks. | Reduces manual labor risks and speeds up operations. | 2024-2025 |

| Enhanced Safety Protocols | New safety regulations and training programs to prevent accidents. | Lowers accident rates and promotes worker safety. | 2023-2024 |

| Green Lifting Solutions | Eco-friendly materials and energy-efficient lifting equipment. | Reduces environmental impact and meets sustainability goals. | 2025 |

| Wearable Technology for Operators | Wearable devices to monitor operator health and safety. | Enhances worker safety and operational efficiency. | 2023-2025 |

Integration of IoT in Lifting Gear for Enhanced Efficiency

The integration of the Internet of Things (IoT) in lifting gear is poised to revolutionize the industry by 2025, driving significant enhancements in operational efficiency and safety. According to a recent report by MarketsandMarkets, the global IoT in lifting equipment market is projected to grow from $1.2 billion in 2023 to $3.6 billion by 2025, reflecting a compound annual growth rate (CAGR) of 30%. This rapid expansion underscores the increasing recognition of IoT technologies as crucial tools for optimizing performance in lifting operations.

IoT-enabled lifting gear offers unprecedented capabilities for real-time monitoring and predictive maintenance. By equipping lifting equipment with smart sensors, operators can gather critical data on load management, equipment health, and usage patterns. A study by McKinsey reports that predictive maintenance can reduce equipment downtime by up to 50%, which not only enhances operational productivity but also extends the lifespan of the equipment. The ability to make data-driven decisions will amplify safety protocols, allowing for timely responses to potential hazards and risks.

Furthermore, the integration of IoT fosters a collaborative environment between machinery and operators, enabling seamless communication and improved workflow. As noted in a report by ResearchAndMarkets, companies that utilize IoT in their lifting operations can achieve a remarkable increase in efficiency, with potential savings of up to 20% in operational costs. This technological shift not only streamlines lifting operations but also positions companies to better meet the demands of an increasingly competitive landscape.

Future Materials: Lightweight and Durable Innovations in Lifting Gear

As the lifting gear industry prepares for 2025, a significant trend is emerging around the development of innovative materials that prioritize both lightweight and durability. The shift towards using advanced composites and high-strength materials is driven by the need for equipment that can withstand rigorous operational demands while minimizing weight. According to a recent market analysis by Grand View Research, the global lifting equipment market is projected to reach USD 56 billion by 2025, with lightweight gear being a key factor in this growth.

Recent advancements in lightweight materials, such as carbon fiber and advanced polymers, are revolutionizing the lifting gear landscape. These materials not only reduce the overall weight of lifting equipment but also enhance its strength and longevity. For instance, tests show that carbon fiber-based products can be up to five times stronger than traditional steel yet significantly lighter, allowing for easier handling and reduced fuel consumption for transport vehicles. The introduction of these materials aligns with the industry's push towards sustainability and efficiency, catering to the increasing demands for eco-friendly solutions in heavy lifting operations.

Additionally, innovations in manufacturing processes like 3D printing are enabling the production of customized lifting gear that meets specific user requirements, further pushing the boundaries of material capabilities. As businesses look to optimize performance and reduce operational costs, investments in lightweight yet durable lifting gear will become essential to staying competitive in the evolving market. Data from the International Crane and Rigging Conference indicates that 70% of operators cite weight reduction as a primary focus for future gear investments, underscoring the importance of these trends in shaping the future of lifting equipment.

Related Posts

-

What is the Best Lifting Tools for Your Needs and How to Choose Them

-

Top 10 Drum Lifting Equipment Options for Safe and Efficient Handling

-

10 Essential Tips for Choosing the Right Industrial Lifting Equipment

-

10 Essential Material Handling Tips for Increased Warehouse Efficiency

-

How to Properly Handle Drums for Safe and Efficient Transport

-

Why Investing in Quality Drum Lifting Equipment Saves Time and Reduces Risks