Blog

Top 10 Manual Handling Lifting Equipment for Safe Work Practices?

In any workplace, safety should always come first. Manual handling lifting equipment plays a crucial role in ensuring safe work practices. These tools help reduce the risk of injuries related to lifting and moving heavy loads. Workers often underestimate the importance of using the right equipment.

Choosing the appropriate manual handling lifting equipment can seem overwhelming. Options range from simple hand trucks to sophisticated lifting devices. Each tool has its unique advantages and limitations. Proper training on these tools is essential, yet often overlooked. Workers might neglect to use equipment, thinking it slows them down.

Incorporating manual handling lifting equipment into daily routines can significantly improve safety. However, some workers still prefer manual lifting, putting themselves at risk. It's important to reflect on our handling practices and prioritize safety. A small change in habits can lead to big improvements in workplace safety.

Understanding Manual Handling and Its Importance in Workplace Safety

Understanding manual handling is crucial for maintaining workplace safety. Many injuries arise from improper lifting techniques. Employees should learn to recognize risks associated with manual handling. This knowledge is key to preventing accidents.

Tip: Always assess the load before lifting. Know its weight and shape. If it’s too heavy or awkward, ask for help. Use lifting aids whenever possible. They reduce strain on your body.

Proper training is essential. Workers should understand how to lift correctly. Bend at the knees. Keep your back straight. This simple technique can prevent many injuries. Over time, some may forget these basic tips. Regular refreshers can reinforce safe practices.

Tip: Take breaks to avoid fatigue. Tired workers are more likely to make mistakes. Everyone should be aware of signs of discomfort or pain. Reporting these issues can help improve safety culture in the workplace.

Common Risks Associated with Manual Lifting and Handling Practices

Manual lifting can pose significant risks in the workplace. Injuries are often due to improper techniques or excessive loads. Back strains are common, resulting from awkward postures. Many workers underestimate the weight they lift daily. Foot injuries may happen if heavy items are dropped. This highlights the importance of awareness in manual handling tasks.

Proper training is essential for safe lifting practices. Workers must learn to assess loads before lifting. They should always keep the load close to the body. A firm grip is vital to prevent dropping items. Yet, many individuals rush through these steps. They assume they know how to lift correctly. This can lead to accidents and injuries that could have been avoided.

Workplaces should promote a culture of safety. Regularly reviewing lifting practices can help. Supervisors must encourage workers to speak up about risks. Creating an environment where lifting techniques are discussed openly can make a difference. Unfortunately, some continue to lift heavy objects alone, ignoring safety protocols. Reflection is necessary to improve these situations.

Overview of Top Manual Handling Lifting Equipment Available Today

Manual handling lifting equipment plays a vital role in ensuring workplace safety. Many tools are designed to reduce the risk of injury during lifting tasks. These devices can help manage heavy loads efficiently, enhancing overall productivity. However, not all equipment suits every situation, and improper use can lead to accidents.

One essential piece of equipment is the lifting sling. These slings come in various materials and shapes, offering flexibility for different loads. While they are great for distributing weight, poor attachment can be risky. It’s crucial to ensure they are secured correctly before lifting. Then there are hoists, which can lift substantial weights with minimal manual effort. But operators need proper training. Miscommunication can lead to mistakes.

Another option is the pallet jack. It's perfect for moving heavy pallets over short distances. Yet, if overloaded, it can become unmanageable. Some may find it challenging to navigate tight spaces. Equipment like dollies and hand trucks assists in transporting small items efficiently. However, users must pay attention to balance. Uneven loads can tip them over, causing spills or injuries. Always consider the specific needs of your workplace when selecting lifting equipment.

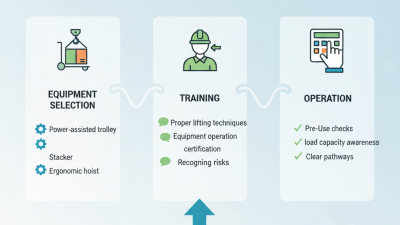

Criteria for Selecting Safe Lifting Equipment for Various Tasks

When selecting lifting equipment for various tasks, safety and effectiveness are paramount. Start by assessing the weight of the load. Overloading equipment can lead to accidents and injuries. Choose equipment rated for at least 25% above the load weight. This extra capacity provides a safety margin that could be lifesaving in unexpected situations.

Consider the nature of the load. Is it awkwardly shaped? Does it have sharp edges? Some lifting devices are designed specifically for certain shapes. Others may not grip securely. Using the right tool for the job can minimize the risk of dropping an item. Ensure the equipment has features like ergonomic handles to promote a safer lifting posture.

Training is essential. Workers need to understand how to use equipment correctly. Poor training can lead to misuse and dangerous situations. Regular refreshers can help keep safety a priority. Reflect on past incidents. Learning from mistakes can enhance safety practices. It’s vital to foster a culture of awareness and accountability in lifting operations.

Best Practices for Training Staff on Manual Handling Techniques

Training staff on manual handling techniques is crucial for workplace safety. According to the Health and Safety Executive (HSE), over 300,000 workers suffer from back injuries each year due to improper lifting. Effective training can significantly reduce these incidents.

Incorporating hands-on practice is vital. Employees should engage in exercises that mimic their daily tasks. Visual aids, like diagrams, can help clarify proper techniques. Regular refresher courses will keep safety practices at the forefront of employees' minds.

Tip: Encourage staff to ask questions during training. Open dialogue can reveal gaps in understanding.

Supervisors must also lead by example. They should demonstrate correct lifting techniques consistently. Employees are more likely to follow protocols when they see their leaders practicing them.

Tip: Use real-life scenarios to discuss challenges in manual handling. This will help staff relate training to their actual experiences.

Assessments are essential to gauge understanding. These checks should occur frequently, helping identify areas for improvement. The feedback should foster an environment of continuous learning.

Related Posts

-

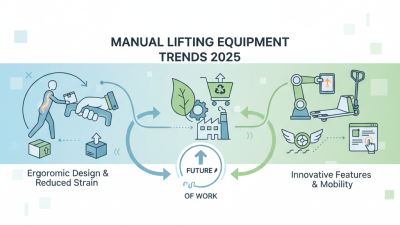

Top Manual Lifting Equipment Trends You Need to Know in 2025

-

2025 Top Manual Handling Lifting Equipment Tips for Safe and Efficient Use

-

What is Drum Handling and How to Safely Manage Drums in Your Workplace

-

10 Essential Tips for Choosing the Right Industrial Lifting Equipment

-

How to Properly Handle Drums for Safe and Efficient Transport

-

10 Essential Material Handling Tips for Increased Warehouse Efficiency