Blog

2025 Top Manual Handling Lifting Equipment Tips for Safe and Efficient Use

In the world of workplace safety, the importance of proper manual handling lifting equipment cannot be overstated. As noted by industry expert Dr. Jane Smith, a leading authority in occupational safety, "The right lifting equipment not only prevents injuries but also enhances overall efficiency in the workplace." This emphasizes the critical role that manual handling lifting equipment plays in safeguarding workers while maintaining productivity.

In 2025, as workplaces evolve and demand for heightened safety protocols increases, the strategies surrounding the use of manual handling lifting equipment will also advance. Understanding the right techniques and tools will be essential for organizations aiming to create a safe environment for their employees. By focusing on the best practices for equipment selection, training, and operation, businesses can significantly reduce the risk of injuries associated with manual handling tasks.

This comprehensive overview aims to provide essential tips for the safe and efficient use of manual handling lifting equipment, ensuring that both employees and employers can thrive in a secure and productive work setting.

Importance of Manual Handling in Workplace Safety

Manual handling is a critical aspect of workplace safety, significantly influencing both employee well-being and operational efficiency. According to the Health and Safety Executive (HSE), manual handling activities contribute to over a third of all workplace injuries in the UK alone, with musculoskeletal disorders (MSDs) being the most common result. This data underscores the urgent need for effective manual handling practices to mitigate risks, ensuring a safer working environment.

Implementing safe manual handling techniques not only aids in reducing injury rates, but it also enhances productivity. A study by the National Institute for Occupational Safety and Health (NIOSH) revealed that proper ergonomics in lifting and handling can lead to a reduction of productivity losses by nearly 20%. This is achieved by minimizing the strain on workers, allowing them to perform tasks efficiently without unnecessary fatigue. Investing in proper training and ergonomic assessments can thus yield substantial benefits, fostering a culture of safety and well-being within the workplace.

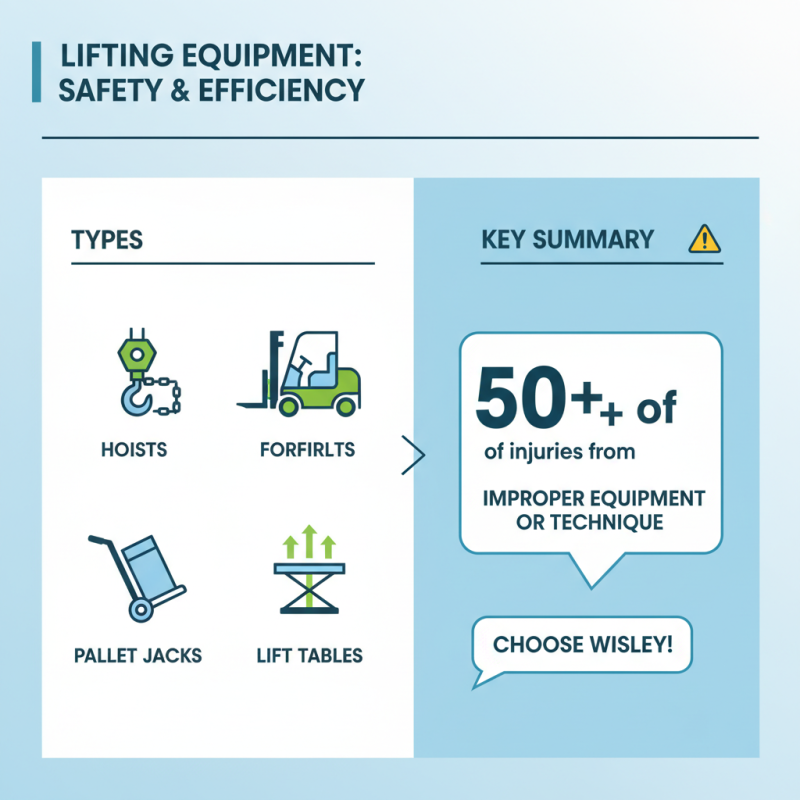

Types of Lifting Equipment and Their Appropriate Uses

When selecting lifting equipment, it's essential to understand the different types available and their appropriate uses to ensure safety and efficiency. Manual handling involves a variety of equipment, including hoists, forklifts, pallet jacks, and lift tables, each designed for specific tasks. According to a report by the Health and Safety Executive (HSE), over 50% of manual handling injuries in the workplace can be attributed to improper lifting techniques or an inadequate choice of equipment.

For light to moderate loads, pallet jacks are widely utilized due to their maneuverability in tight spaces and ability to handle weights up to 5,500 pounds. They are ideal for moving goods over short distances within warehouses. In contrast, for heavier items or when vertical movement is necessary, lift tables offer excellent versatility by allowing operators to raise materials to a comfortable working height, reducing the risk of musculoskeletal injuries. The American National Standards Institute (ANSI) emphasizes that using the right lifting equipment not only enhances productivity but also plays a crucial role in minimizing workplace injuries, demonstrating the importance of tailored solutions for varying lifting tasks.

Employing the right lifting equipment in accordance with industry standards is vital for creating a safe work environment. Research indicates that 40% of workplace accidents involve manual handling, reflecting the necessity for organizations to invest in appropriate training and equipment that align with the specific handling requirements of their operations. By adhering to guidelines and selecting the right tools, businesses can significantly reduce injury rates and improve overall operational efficiency.

Best Practices for Lifting Techniques and Posture

When it comes to manual handling and lifting, proper technique and posture are crucial for ensuring both safety and efficiency. Adopting the right lifting techniques can significantly reduce the risk of injuries, enhance productivity, and improve overall workplace ergonomics. One essential tip is to maintain a wide stance with feet shoulder-width apart. This base provides stability and helps to distribute weight evenly, which is vital when lifting heavy loads.

Additionally, it’s important to bend at the hips and knees while keeping your back straight. This posture minimizes strain on the spine and allows you to use the strength of your legs, which are much stronger than your back muscles. As you lift, engage your core to provide extra support and maintain balance throughout the movement. Remember, always lift with a controlled motion; jerky or sudden movements can lead to injuries.

Another valuable tip is to keep the load close to your body. This reduces the lever effect on your back and puts less stress on your muscles and joints. If an item is too heavy or awkward to lift alone, don’t hesitate to ask for help or use mechanical aids like forklifts or dollies. By prioritizing proper lifting techniques and maintaining a mindful posture, you can ensure a safer and more efficient manual handling experience.

Regular Maintenance and Inspection of Lifting Equipment

Regular maintenance and inspection of lifting equipment are critical for ensuring safe and efficient operations in any manual handling environment. Scheduled maintenance helps identify wear and tear, ensuring that the equipment operates optimally and minimizes the risk of malfunctions during use. By adhering to a structured maintenance plan, organizations can prevent costly downtimes and enhance the safety of their workforce. Regular checks can also help in detecting potential safety hazards before they exacerbate into serious incidents, providing peace of mind for operators and management alike.

In addition to preventive measures, thorough inspections play a vital role in compliance with safety standards and regulations. Inspections should be performed by qualified personnel who understand the specific requirements of the equipment being used. They should assess various components, including lifting mechanisms, safety devices, and any wear parts. Documenting the results of these inspections not only aids in maintaining accountability but also ensures that any necessary repairs or replacements are addressed promptly. By fostering a culture of safety through regular maintenance and diligent inspections, workplaces can significantly enhance the longevity of their lifting equipment while safeguarding their employees.

2025 Top Manual Handling Lifting Equipment Tips for Safe and Efficient Use

| Tip | Description | Frequency of Inspection | Responsible Party |

|---|---|---|---|

| Regular Visual Checks | Inspect for any visible signs of wear and tear before each use. | Daily | Operator |

| Load Capacity Check | Verify that the equipment is suitable for the intended load. | Before each use | Operator |

| Periodic Maintenance | Conduct detailed inspections and servicing. | Monthly | Maintenance Team |

| Competency Training | Ensure operators are trained in safe lifting techniques. | As needed | Safety Officer |

| Emergency Procedures | Review and update emergency procedures regularly. | Quarterly | Management |

Training and Education for Safe Manual Handling Practices

Effective training and education are essential components for ensuring safe manual handling practices in any workplace. When employees are equipped with the right knowledge and skills, they can minimize the risks associated with lifting and carrying heavy objects. Training should focus on proper techniques such as maintaining a stable base, using the legs for lifting rather than the back, and avoiding awkward postures. Regular training sessions not only enhance employee confidence but also promote a culture of safety within the organization.

To further improve manual handling safety, consider implementing the following tips. First, always assess the load before attempting to lift it. Determine its weight, shape, and size, and if necessary, seek assistance or use handling equipment. Second, encourage the use of appropriate lifting aids, such as trolleys or hoists, to reduce the physical strain on workers. Finally, maintain a clutter-free work environment; this reduces trip hazards and allows for safe, efficient movement when handling materials.

Incorporating these tips into your training programs reinforces the importance of safety in manual handling. Providing continuous education and practical demonstrations can significantly enhance employee performance and well-being. By prioritizing these elements, organizations can ensure that their workforce remains healthy and efficient while reducing the likelihood of workplace injuries.

2025 Tips for Safe Manual Handling Practices

Related Posts

-

Top Lifting Gear Trends for 2025 You Need to Know About Now

-

Top Manual Lifting Equipment Trends You Need to Know in 2025

-

Top 10 Best Material Hoists for Efficient Construction Projects in 2023

-

What is a Material Handling Cart and How Does it Improve Efficiency

-

Top Material Handling Products to Boost Efficiency in 2025

-

What is the Best Lifting Tools for Your Needs and How to Choose Them