Blog

Top Manual Lifting Equipment Trends You Need to Know in 2025

As we look forward to the year 2025, the landscape of manual lifting equipment is poised for significant evolution. With advancements in technology and a heightened focus on workplace safety, the trends surrounding manual lifting equipment are becoming increasingly crucial for businesses aiming to enhance operational efficiency while prioritizing employee well-being. These trends are expected to reflect a growing emphasis on ergonomic design, sustainability, and innovative features that facilitate easier handling and reduced physical strain.

In this changing environment, organizations are recognizing the importance of adapting their manual lifting equipment to meet both the demands of their workforce and the challenges posed by modern logistics. The introduction of lightweight materials, improved mobility features, and user-friendly interfaces are just a few ways manual lifting equipment is evolving to support a safer and more productive working environment. As we delve into these trends, we will explore how they can potentially reshape employee interactions with equipment, streamline processes, and ultimately contribute to more efficient operational practices across various industries.

Top Innovations in Manual Lifting Equipment for Enhanced Ergonomics

The ergonomic design of manual lifting equipment has become increasingly critical as businesses strive to enhance workplace safety and improve worker wellbeing. According to a report from the National Institute for Occupational Safety and Health (NIOSH), approximately 30% of all workplace injuries are related to manual handling activities. This statistic underscores the importance of innovation in lifting equipment that prioritizes ergonomics. In 2025, companies are expected to adopt technologies such as adjustable lifting heights, intuitive controls, and lightweight materials that reduce strain on workers and minimize the potential for injury.

Recent advancements in manual lifting equipment are focused on incorporating smart technologies that provide real-time data and feedback to users. For example, sensors can monitor lifting techniques and offer suggestions to maintain proper posture, thus reducing the risk of musculoskeletal disorders. The Global Ergonomics Association has projected a market growth of 18% in ergonomic lifting solutions through 2025, indicating a strong trend towards investing in equipment that not only enhances productivity but also safeguards employee health. As organizations increasingly recognize the connection between ergonomics and operational efficiency, the trend of prioritizing innovative manual lifting solutions is set to transform workplaces across various industries.

Top Manual Lifting Equipment Trends You Need to Know in 2025

This bar chart illustrates the key trends in manual lifting equipment expected to dominate the market in 2025, emphasizing adoption rates for ergonomic designs, smart technologies, sustainability practices, user training, and increased load capacities.

Impact of Automation on Manual Lifting Equipment Trends by 2025

The advent of automation is significantly reshaping the landscape of manual lifting equipment, creating a shift towards more sophisticated and efficient solutions by 2025. As industries increasingly seek productivity enhancements, the integration of automated systems with manual lifting tools is becoming more prominent. This trend will likely lead to the development of hybrid lifting solutions that combine human flexibility with machine precision, allowing operators to manage heavier loads with reduced risk of injury. Moreover, innovations like automated hoists and powered lift-assist devices are on the rise, promising to transform traditional manual tasks into streamlined processes.

Additionally, the influence of data analytics and IoT (Internet of Things) technology cannot be overlooked. As manual lifting equipment becomes interconnected, real-time data collection and monitoring will enhance operational efficiency and safety. Companies will utilize predictive maintenance features, whereby potential issues are identified before they escalate, significantly lowering downtime and ensuring that equipment remains in optimal working condition. This convergence of automation and manual handling not only aims to elevate workplace safety but also enables businesses to maximize their output while minimizing labor costs. The future of manual lifting equipment is poised to be a dynamic fusion of human skill and technological advancement.

Top Manual Lifting Equipment Trends You Need to Know in 2025 - Impact of Automation on Manual Lifting Equipment Trends by 2025

| Trend | Description | Projected Growth Rate (%) | Impact of Automation |

|---|---|---|---|

| Increased Ergonomics | Focus on ergonomic designs to reduce worker injuries. | 12% | Automation aids in design accuracy and user feedback. |

| Smart Lifting Devices | Integration of IoT for real-time monitoring and data analysis. | 15% | Devices enhance connectivity and operational efficiency. |

| Sustainability Measures | Use of eco-friendly materials in manufacturing lifting equipment. | 10% | Automation optimizes resource management in production. |

| Customized Solutions | Tailored lifting solutions to meet specific industry needs. | 20% | Automation supports rapid prototyping for customization. |

| Training and Safety Protocols | Enhanced training programs utilizing VR and AR technologies. | 8% | Automation can provide immersive training environments. |

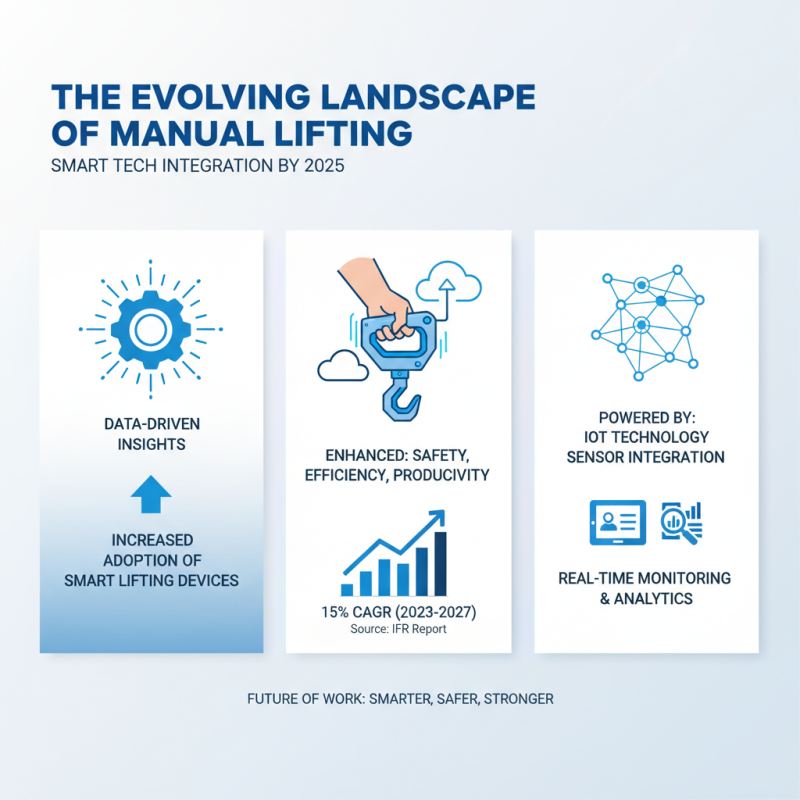

Data-Driven Insights: The Rise of Smart Manual Lifting Devices

The landscape of manual lifting equipment is rapidly evolving, with significant emphasis on the integration of smart technologies. As we approach 2025, data-driven insights reveal a notable trend towards the adoption of smart manual lifting devices, which are designed to enhance safety, efficiency, and productivity in various industries. According to a recent report by the International Federation of Robotics (IFR), the smart lifting equipment market is projected to grow at a remarkable compound annual growth rate (CAGR) of 15% between 2023 and 2027. This growth is largely attributed to advancements in Internet of Things (IoT) technology and sensor integration, which allow for real-time monitoring and data analytics.

The rise of smart manual lifting devices not only transforms operational practices but also addresses worker safety concerns. A study conducted by the Occupational Safety and Health Administration (OSHA) indicates that more than one-third of workplace injuries are linked to manual handling. Smart lifting equipment equipped with sensors can identify potential hazards and optimize lifting techniques, thereby reducing the risk of injuries. Furthermore, tools that utilize AI algorithms enable customization of lifting parameters based on specific task requirements, increasing both safety and efficiency. As industries strive to create safer work environments, the implementation of these smart solutions will likely become a standard practice in the near future.

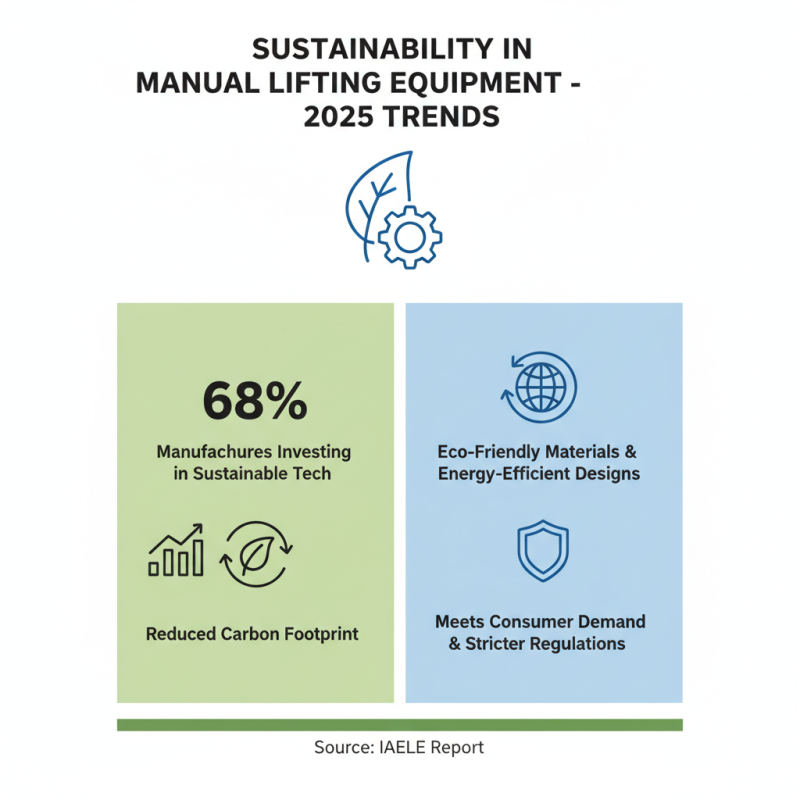

Sustainability Practices in the Manual Lifting Equipment Industry

As the manual lifting equipment industry adapts to evolving market demands, sustainability has emerged as a crucial theme for 2025. Companies are increasingly focusing on eco-friendly materials and energy-efficient designs. According to a recent report by the International Association of Lifting Equipment Engineers (IAELE), around 68% of manufacturers are investing in sustainable technologies to reduce their carbon footprint. These practices not only appeal to environmentally conscious consumers but also comply with stricter regulations regarding emissions and resource use.

Transitioning towards sustainability can involve several innovative practices. For instance, many companies are opting for lightweight, recyclable materials that enhance efficiency in lifting operations while minimizing environmental impact. Additionally, energy-efficient designs help to lower power consumption during lifting tasks, thereby reducing overall operational costs. Implementing these sustainable practices is not just beneficial for the environment; it can also lead to enhanced brand loyalty and customer trust as companies demonstrate their commitment to corporate social responsibility.

**Tips:** Consider conducting lifecycle assessments of your lifting equipment to identify areas for improvement in sustainability. Additionally, engaging with suppliers who prioritize green materials can significantly enhance your product's environmental profile. Lastly, training your staff on sustainability practices is crucial; an informed team will be more adept at implementing these initiatives effectively.

Market Growth and Competitive Analysis of Manual Lifting Equipment by 2025

The manual lifting equipment market is poised for significant growth through 2025, driven by the increasing demand for ergonomic solutions across various industries. According to a recent analysis by a leading consulting firm, the global market for manual lifting equipment is expected to reach USD 2.5 billion by the end of 2025, growing at a compound annual growth rate (CAGR) of 6.2%. This growth is largely attributed to the rising awareness of occupational health and safety regulations, compelling companies to invest in safer lifting solutions to reduce workplace injuries.

Competitive analysis shows that companies focusing on innovative product designs and enhanced user ergonomics will have a strategic advantage. Key trends include the integration of smart technologies into manual lifting equipment, such as load monitoring systems and user-friendly interfaces. Furthermore, the Asia-Pacific region is anticipated to lead the market during this period, fueled by rapid industrialization and a growing workforce in countries like China and India.

Tips: When considering manual lifting equipment, always assess the weight capacity and ergonomic features to ensure safety and efficiency in operations. Regular training and safety audits can also significantly mitigate risks associated with manual lifting, enhancing overall workplace safety standards. Implementing a proactive approach towards equipment maintenance will further extend the longevity and performance of manual lifting solutions.

Related Posts

-

Top 10 Drum Lifting Equipment Options for Safe and Efficient Handling

-

Top Material Handling Products to Boost Efficiency in 2025

-

Top 10 Best Material Hoists for Efficient Construction Projects in 2023

-

Why Investing in Quality Drum Lifting Equipment Saves Time and Reduces Risks

-

10 Essential Material Handling Tips for Increased Warehouse Efficiency

-

What is Drum Handling and How to Safely Manage Drums in Your Workplace