Blog

Top Material Handling Products to Boost Efficiency in 2025

In the fast-evolving landscape of warehousing and logistics, the significance of efficient material handling products cannot be overstated. As businesses strive to enhance productivity and streamline operations in 2025, the selection and implementation of advanced material handling solutions become paramount. These products not only optimize workflows but also contribute to a safer and more organized work environment, ultimately leading to increased profitability and sustainability.

As we look ahead, it’s crucial to understand the key innovations and trends shaping the material handling industry. From automated systems that reduce manual labor to ergonomic designs that enhance worker safety, staying updated on the latest material handling products is essential for any organization aiming to stay competitive. This article will explore the top material handling products set to boost efficiency, emphasizing their role in transforming operations and driving success in the coming years. Embracing these tools will not only improve operational efficiency but also foster a culture of continuous improvement throughout the organization.

Top Material Handling Products to Boost Efficiency in 2025

The landscape of material handling is evolving rapidly, driven by the need for increased efficiency and productivity in warehouses and manufacturing environments. As businesses look towards 2025, innovations in material handling products are anticipated to significantly enhance operational workflows. According to a report by Logistics Management, companies that adopt advanced material handling technologies can see efficiency improvements of up to 30%. This shift is largely due to the integration of automation and data analytics, which streamline processes and reduce human error.

Among the top contenders in the material handling products of 2025 are automated guided vehicles (AGVs) and smart conveyor systems. AGVs are projected to account for a substantial share of the market, with research indicating that their user adoption will grow by over 25% annually. These vehicles not only facilitate the movement of goods without the need for extensive human oversight but also contribute to safer work environments by minimizing the risks associated with manual handling. Meanwhile, smart conveyor systems, equipped with sensors and IoT capabilities, enable real-time monitoring and analytics, fostering significant improvements in inventory management and order fulfillment processes. Such advancements are critical as organizations strive to meet increasing consumer demands for faster delivery times and accuracy in fulfillment.

With the expected growth in e-commerce and the necessity for agile supply chains, the focus on optimizing material handling will become more pronounced. Data from industry analysts suggest that investment in these advanced systems will be crucial, as companies face pressure from both competition and consumer expectations. By integrating top-tier material handling solutions, businesses can not only bolster their operational efficiency but also position themselves favorably in a rapidly changing market landscape.

Emerging Trends in Material Handling Technologies for 2025

In 2025, the landscape of material handling technologies is expected to undergo significant changes driven by advancements in automation and artificial intelligence. According to a recent report by the Material Handling Industry of America, the global market for material handling equipment is projected to grow by 7.5% annually, reaching approximately $220 billion by 2025. This growth reflects the increasing reliance on automation solutions, including autonomous vehicles and robotic systems, which are designed to enhance efficiency and reduce operational costs for businesses across sectors.

One of the foremost emerging trends is the integration of IoT (Internet of Things) technologies into material handling systems. RFID tags and sensors are becoming commonplace, offering real-time tracking of goods and assets throughout the supply chain. This technology not only enables improved inventory management but also facilitates predictive maintenance, reducing downtime. A report from the Warehousing Education and Research Council indicates that companies adopting IoT solutions can expect a 15% increase in operational efficiency, showcasing the impact of these innovations on productivity.

Moreover, sustainability is becoming a key focus within material handling operations. The increasing demand for eco-friendly practices encourages companies to invest in energy-efficient equipment and sustainable materials. A study conducted by the Logistics Management shows that 65% of organizations are prioritizing green logistics initiatives. As a result, the convergence of sustainability and technology in material handling is expected to drive further innovations, ultimately transforming warehouse and distribution center operations in the coming years.

Top Material Handling Products to Boost Efficiency in 2025

Key Features of High-Performance Material Handling Equipment

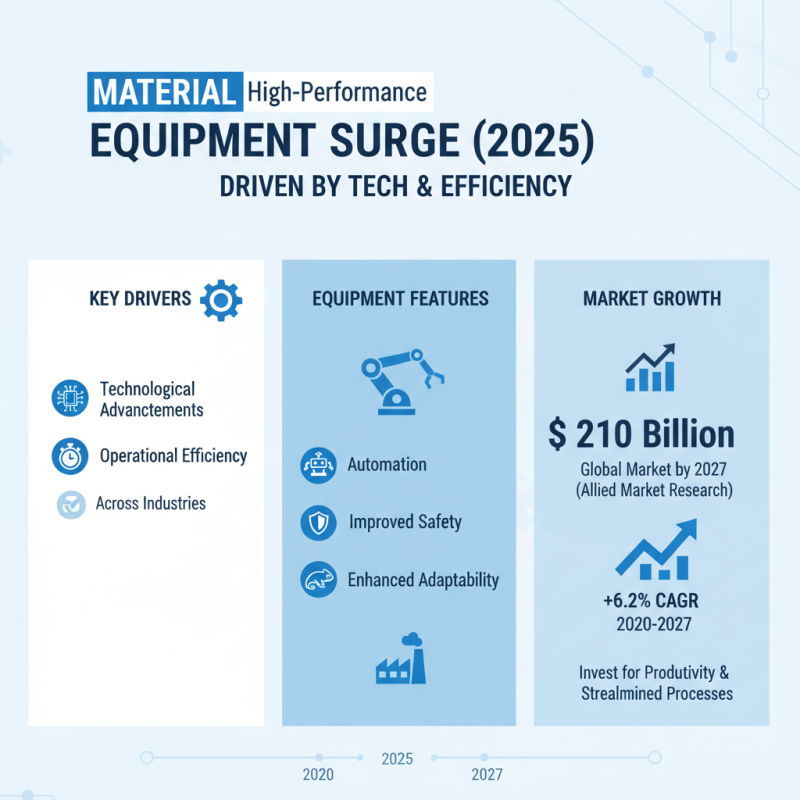

In 2025, the demand for high-performance material handling equipment is projected to surge, driven by advancements in technology and the growing emphasis on operational efficiency across industries. Key features of such equipment include automation, improved safety mechanisms, and enhanced adaptability to various environments. According to a recent industry report by Allied Market Research, the global material handling market is expected to reach $210 billion by 2027, growing at a compound annual growth rate (CAGR) of 6.2% from 2020 to 2027. This growth underscores the importance of investing in products that can streamline processes and increase productivity.

Automation has emerged as a crucial element in the design of modern material handling equipment. Equipment that integrates artificial intelligence and machine learning can optimize workflows and reduce human error. For instance, autonomous mobile robots (AMRs) are becoming increasingly prevalent, with a study by Grand View Research estimating the AMR market to hit $23 billion by 2027, exhibiting a CAGR of 32.2%. Additionally, modern systems prioritize safety features such as collision detection and ergonomic designs, ensuring a safer work environment for employees. These enhancements not only mitigate risks but also lead to significant savings in insurance and liability costs.

Adaptability is another vital characteristic of high-performance material handling products. Equipment designed to handle a variety of payloads and work seamlessly in different settings can significantly enhance operational flexibility. As noted in a report by Research and Markets, businesses that implement adaptable material handling solutions can improve their supply chain efficiency by up to 30%. By focusing on these key features, companies can capitalize on the material handling innovations of 2025 and beyond, positioning themselves as leaders in their respective markets.

Impact of Automation on Efficiency in Material Handling Processes

Automation is set to revolutionize material handling processes in 2025, significantly enhancing operational efficiency. As businesses face the increasing demand for faster and more reliable supply chain solutions, integrating automated systems like robotics and artificial intelligence will streamline workflows.

Automated guided vehicles (AGVs) and robotic arms are capable of carrying out repetitive tasks, thereby reducing human error and minimizing downtime. This shift not only speeds up the handling of materials but also allows human workers to focus on tasks that require critical thinking and problem-solving skills.

Moreover, the implementation of automated systems facilitates real-time data collection and analysis, providing valuable insights into operational performance. By leveraging this data, companies can optimize inventory management and improve overall logistics strategies. Predictive maintenance powered by machine learning algorithms ensures that equipment operates efficiently, thus avoiding costly breakdowns. As a result, organizations can achieve a higher level of productivity and responsiveness to market changes, positioning themselves competitively in a fast-evolving landscape. The impact of automation is not just about replacing manual labor; it's about creating a synergy that enhances both efficiency and workplace safety.

Sustainability in Material Handling: Eco-Friendly Product Innovations

As we look toward 2025, sustainability in material handling is becoming increasingly crucial for businesses aiming to boost efficiency while reducing environmental impact. Innovations in eco-friendly products are at the forefront of this shift, with an array of solutions designed to minimize waste and energy consumption. For instance, reusable packaging systems and biodegradable materials are gaining traction, offering companies a way to transport goods without the burden of excess plastic waste.

Tips: Consider transitioning to energy-efficient equipment, such as electric forklifts and automated guided vehicles (AGVs). These alternatives not only lower carbon emissions but also help in reducing operational costs in the long run. Implementing a waste reduction strategy can further enhance sustainability efforts by recycling materials and choosing suppliers committed to eco-friendly practices.

In addition, optimizing warehouse layouts using sustainable practices can lead to significant gains in efficiency. By incorporating natural light and proper ventilation into design plans, facilities can reduce their reliance on artificial lighting and improve air quality. The continuous evolution of materials and technologies promises exciting opportunities for companies willing to embrace sustainable innovations in their material handling processes.

Top Material Handling Products to Boost Efficiency in 2025 - Sustainability in Material Handling: Eco-Friendly Product Innovations

| Product Type | Features | Sustainability Aspect | Efficiency Gain (%) | Estimated Cost ($) |

|---|---|---|---|---|

| Electric Pallet Jack | Compact design, wireless control | Uses recycled materials, energy-efficient design | 25 | 3,500 |

| Automated Storage Systems | Robotic integration, real-time inventory | Low energy consumption, recyclable parts | 40 | 15,000 |

| Eco-Friendly Forklifts | Hydrogen fuel or electric powered | Zero emissions, made from sustainable materials | 30 | 40,000 |

| Recyclable Packaging Solutions | Lightweight, secure transport | 100% recyclable materials | 20 | 500 |

| Smart Conveyors | Integrated sensors, automated sorting | Energy efficient and modular design | 35 | 10,000 |

Related Posts

-

Top 5 Innovative Material Handling Solutions to Enhance Your Warehouse Efficiency

-

Top 10 Best Material Hoists for Efficient Construction Projects in 2023

-

Why Investing in Quality Drum Lifting Equipment Saves Time and Reduces Risks

-

10 Essential Tips for Choosing the Right Industrial Lifting Equipment

-

What is the Best Lifting Tools for Your Needs and How to Choose Them

-

How to Properly Handle Drums for Safe and Efficient Transport