For many manufacturers, choosing between available stock equipment and waiting for custom material handling equipment has become a familiar dilemma. While standard machinery may seem quicker or cheaper, production equipment is a decades-long investment. The wrong fit can mean inefficiency, higher costs, and safety risks that compound over time.

Choosing custom material handling equipment ensures that your system aligns with your exact processes, facility requirements, and safety standards. That means fewer compromises, smoother operations, and better long-term returns.

Key Advantages of Custom Equipment

- Peak Efficiency

Tailoring your custom material handling equipment to specific handling needs eliminates bottlenecks, reduces spills or product loss, and helps maintain a consistent production rhythm. - Lower Lifetime Costs

While custom systems may carry higher initial costs, they pay off in lower labor expenses, energy efficiency, and reduced downtime. Faster throughput means stronger ROI over the long run. - Improved Safety & Compliance

Custom designs can minimize operator exposure, control dust, and meet strict hygiene or regulatory requirements — essential in industries like food, pharmaceutical, and chemical processing.

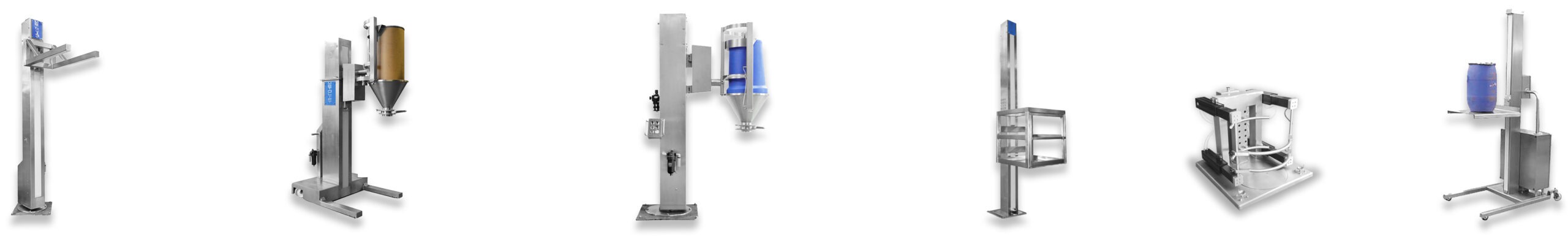

Spotlight: METO Systems Custom Equipment

METO Systems designs and manufactures stainless-steel custom material handling equipment that adapts to a wide range of industrial applications. Here are three categories of equipment that highlight the value of custom design:

Drum Inverters

When product transfer requires containment and precision, drum inverters provide safe, controlled discharge by rotating drums 180°. These units can be engineered with dust-tight seals, enclosed transfers, and operator-friendly controls to protect both product integrity and worker safety. Custom lift attachments and mounting options ensure compatibility with your specific operation.

Drum Dumpers & Tippers

For processes that rely on fast, repeatable unloading, dumpers and tippers can be designed to handle a variety of containers, from drums to boxes and pails. Options like tapered or necked chutes, sanitary finishes, and right- or left-side discharge give you the flexibility to match the exact layout of your line. Custom lift capacities and automation controls help streamline operations and reduce manual handling.

Drum Blenders & Tumblers

Unlike container blenders, tumblers rotate drums end-over-end to mix powders, resuspend solids, or break up clumps. These machines can be configured for mobility, integrated control systems, or sanitary finishes to meet production or cleanroom standards. They’re especially useful when processing multiple materials that require consistent blending without opening containers.

Customization Makes the Difference

Whether you need dust-tight containment, ergonomic handling, or a system that integrates seamlessly with your existing production line, custom material handling equipment eliminates the compromises of stock solutions. With METO Systems’ engineering expertise, you can design equipment that saves time, reduces risk, and adapts perfectly to your facility.

Partner with METO Systems

METO Systems offers some of the shortest lead times in the industry thanks to its lean manufacturing approach. From designing a single piece of equipment to reimagining your entire line, the team provides comprehensive support at every stage of development.

Ready to explore a custom solution? Contact METO Systems at 201-405-0311 or through their sales team contact page to learn how custom material handling equipment can help your business achieve lasting efficiency.

About METO Systems

For over 50 years, METO Systems has been a leading supplier of process and material handling equipment for various industries, including Pharmaceuticals, Fine Chemicals, Nutraceuticals, and Food. Our dedicated staff is here to support you with all your engineering design and installation questions.