For many manufacturers, choosing between available stock equipment and waiting for custom material handling equipment has become a familiar dilemma. While standard machinery may seem quicker or cheaper, production equipment is a decades-long investment. The wrong fit can mean inefficiency, higher costs, and safety risks that compound over time.

In industries such as pharmaceuticals, fine chemicals, and nutraceuticals, precision in dry processing and bulk solids handling is critical. Consistency, safety, and product quality depend on advanced blending technology that can keep up with evolving production demands. Companies are increasingly investing in automated and reliable systems to ensure efficient workflows, safeguard materials, and maintain the highest levels of compliance.

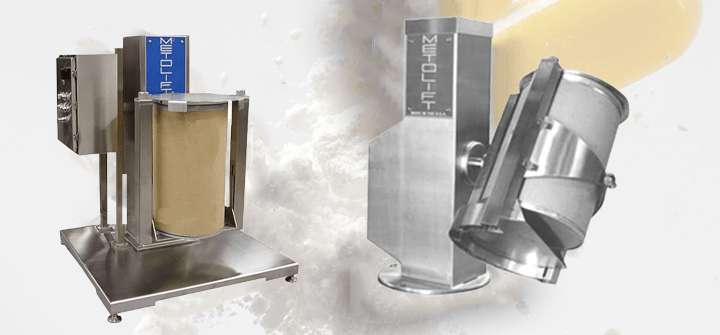

Drum blenders, also known as drum tumblers, are industrial mixing devices that uniformly blend dry powders and granules. They are also commonly used to keep ingredients in liquid suspension and break up powder clumps before discharge.

In the realm of powder processing, the choice of blending equipment plays a crucial role in optimizing efficiency and minimizing challenges associated with traditional blending methods. In this article, we explore the advantages of in-bin blending and how it stands out in comparison to traditional fixed-shell blenders.

Efficient material handling is a cornerstone of productivity across industries. The right equipment can significantly improve workflow efficiency, enhance safety, and reduce labor costs. In this article, we will explore three types of material handling equipment: drum tilters, FIBC (Flexible Intermediate Bulk Container) column lifts, and drum blenders, and showcase their diverse applications in various industries.

Dry blending is a vital step in the production of pharmaceutical drugs. These substances are usually powders but may also be in the form of granules. The active pharmaceutical ingredient or API is blended with a non-active ingredient known as an excipient to produce tablets. The excipients can serve different purposes; for example, they can serve as carriers for the active ingredient.

Powder flow problems can cause frustration and create backups resulting in expensive downtime and the production of substandard products. Powders can act like solids and liquids and lead to product flow issues. Flow issues can result from a product’s handling, storage, and uniform processing, including too much or insufficient blending.

The current state of the supply chain has caused consumers and business buyers to consider whether to wait for what they want to become available or settle for a product that is below their usual standard. If, for example, you are in the market for a new car, you have probably experienced this firsthand.

Blending is a critical process in many industries, including food, pharmaceutical, nutraceutical, cosmetic, and chemical, to name a few. It comes with the risk of inconsistency, cross-contamination, product exposure, and loss but METO Systems brings you a range of efficient stainless-steel blenders that ensure the process occurs quickly, safely, and hygienically.

Tumble Blenders, also known as drum blenders, are widely used in the pharmaceutical industry, food industry, chemical industry, and electron industry to mix dry powder. Especially for materials with a high-quality mix demand or multi-product, multi-volume blends.