Drum conditioners, also recognized as drum massagers, play a crucial role in diverse industries such as food, chemical, and pharmaceutical. These units are specifically designed to address the challenges associated with packed or solidified materials within dry powder drums.

Powder flow problems can cause frustration and create backups resulting in expensive downtime and the production of substandard products. Powders can act like solids and liquids and lead to product flow issues. Flow issues can result from a product’s handling, storage, and uniform processing, including too much or insufficient blending.

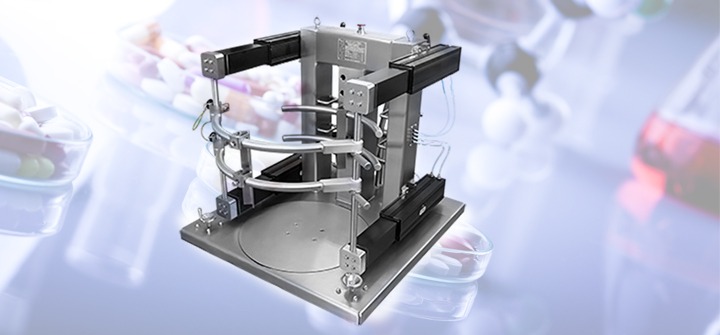

Having a well-designed Drum Conditioner is essential for safely removing the hardened product from drums or boxes in the dry processing and bulk solids handling industry

Drum Conditioners also referred to as Drum Massagers, are used to break up packed or solidified material. When drums of dry powder become interlocked through road transport, heat, humidity, or simply from storage over time, it becomes difficult to produce material flow, or sometimes, any flow at all.

Drum Conditioners also referred to as Drum Massagers, are used to break up packed or solidified material. When drums of dry powder become interlocked through road transport, heat, humidity, or simply from storage over time, it becomes difficult to produce material flow, or sometimes, any flow at all.