Flexible Intermediate Bulk Containers (FIBCs), or bulk bags, remain an industry-standard solution for the clean, efficient transport and storage of dry materials—ranging from resins and powders to seeds, granules, and pharmaceutical ingredients. Their flexibility, reusability, and low environmental impact make them ideal for sectors with high demands for performance and sustainability.

Efficient material handling is a cornerstone of productivity across industries. The right equipment can significantly improve workflow efficiency, enhance safety, and reduce labor costs. In this article, we will explore three types of material handling equipment: drum tilters, FIBC (Flexible Intermediate Bulk Container) column lifts, and drum blenders, and showcase their diverse applications in various industries.

As we witness the impact of climate change around the world, the drive for corporate sustainability initiatives has never been greater. Consumer demands and governmental policies for greener packaging and manufacturing solutions have increased the pressure on businesses globally to move to more sustainable solutions.

FIBC (Flexible Intermediate Bulk Container) bags are highly durable and reusable. They are usually referred to as bulk bags and are used for the transportation of dry bulk goods such as fertilizers, plastic granules, seeds, resins, and powders. This makes them suitable for use in a wide variety of industries.

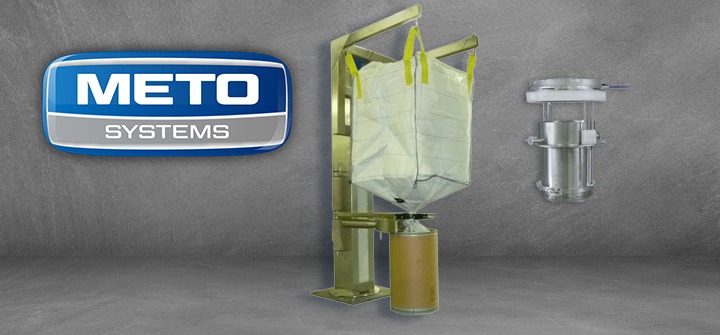

For more than 50 years, METO Systems has been a leading supplier of process and material handling equipment for the Pharmaceutical, Fine Chemicals, Nutraceuticals, and Food industries. We manufacture state-of-the-art, Current Good Manufacturing Practice (CGMP), stainless-steel material handling and processing equipment. All equipment is designed for a lifetime of reliable use, with minimal routine maintenance needed.