In today’s manufacturing and processing environments, safety and efficiency aren’t optional — they’re essential. The challenge is finding equipment that not only meets the rigorous demands of material handling but also supports hygienic operations. That’s where METO Systems’ Stationary Column Lifts for clean process areas deliver a competitive advantage.

In industries where efficiency, cleanliness, and precision are essential, the right discharge valve can significantly enhance your process. METO Systems provides a comprehensive range of application-specific discharge valves designed for the Pharmaceutical, Food, Cosmetic, and Fine Chemical industries. Available in both manual and automated configurations, these valves help manufacturers maintain clean, controlled, and efficient material flow throughout their operations.

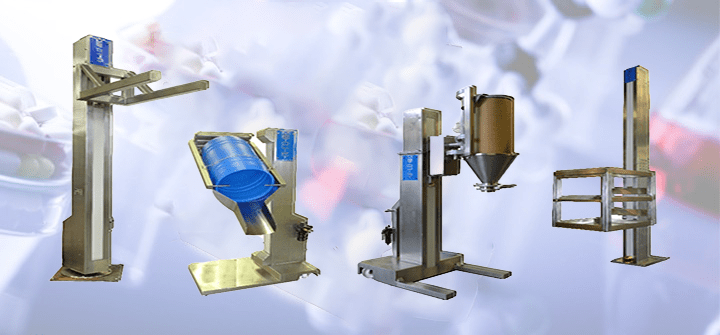

In the dynamic landscape of food and drug manufacturing, efficiency and precision are paramount. METO Systems takes center stage with its innovative solutions, specifically designed to meet the diverse needs of industries such as pharmaceuticals, food, cosmetics, and fine chemicals.

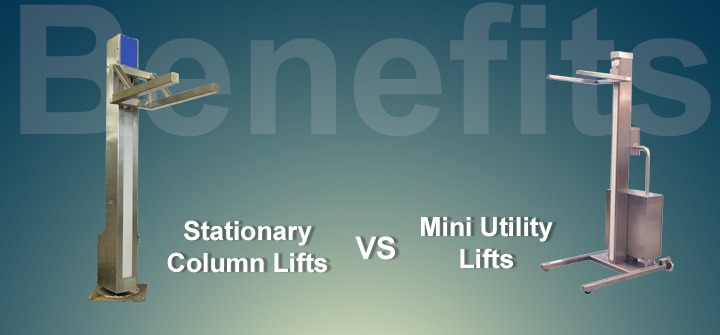

Efficient material handling is crucial in the pharmaceutical, nutraceutical, and food processing industries, where precision and hygiene are paramount. In this article, we will compare and contrast stationary column lifts and mini utility lifts, evaluating their suitability for use in these industries.

Platform lifts, also known as stationary column lifts, are a smooth, efficient way to move products, containers, tools, and equipment to various locations in a manufacturing facility. They can reach separate floors, elevated charging chutes, and positions both above and below processing equipment. Our column lifts provide simple, reliable, ergonomic solutions that ensure the safety of the operator when heavy loads need to be lifted and handled.