When it comes to storing and transporting liquids, powders, or semi-solids, not all containers are created equal. Stainless steel Intermediate Bulk Containers (IBCs) offer a durable, hygienic, and cost-effective solution trusted by industries ranging from pharmaceuticals to agriculture.

So, what makes stainless steel IBCs such a reliable choice?

Built to Last

Stainless steel IBCs are designed to withstand the rigors of frequent transport and harsh industrial environments. Their robust construction offers a longer service life compared to plastic alternatives, which are more prone to cracking, wear, and chemical degradation.

Corrosion-Resistant Confidence

Chemical compatibility is a primary concern when handling sensitive or hazardous materials. Thanks to stainless steel’s natural resistance to corrosion, these IBCs are ideal for transporting a wide range of materials, including acids and aggressive solvents, without compromising safety or integrity.

Clean, Sterile, and Safe

In industries where hygiene is non-negotiable, such as food processing, beverages, and pharmaceuticals, stainless steel shines. These containers are easy to clean, sterilize, and maintain, ensuring your materials are handled under the highest sanitary conditions.

Versatile Across Materials

Whether you’re dealing with liquids, powders, granules, or slurries, stainless steel IBCs can handle the job. Their adaptability makes them a go-to container for a wide range of applications, reducing the need for multiple container types.

Long-Term Value

While stainless steel IBCs may cost more upfront, their durability and reusability offer significant long-term savings. A reduced need for replacement, fewer contamination risks, and less waste result in a better return on your investment.

Space-Smart Design

Thanks to their cubic shape, stainless steel IBCs maximize space efficiency in both storage and transport. They’re easier to stack and store than drums or irregular-shaped containers, making them a practical choice for facilities where every square foot counts.

Industries That Rely on Stainless Steel IBCs:

Chemical – Safe handling of hazardous and reactive materials

Food & Beverage – Transporting ingredients and finished goods

Pharmaceuticals – Sterile storage for raw materials and medications

Agriculture – Storing fertilizers, pesticides, and nutrients

Oil & Gas – Moving lubricants, fuels, and drilling fluids

Water Treatment – Handling chemicals for purification

Cosmetics – Transporting ingredients and final product batches

The Bottom Line

Stainless steel IBCs deliver a winning combination of safety, strength, and versatility. Whether you’re focused on hygiene, long-term cost savings, or chemical compatibility, these containers are engineered to meet the demands of modern industry and exceed expectations.

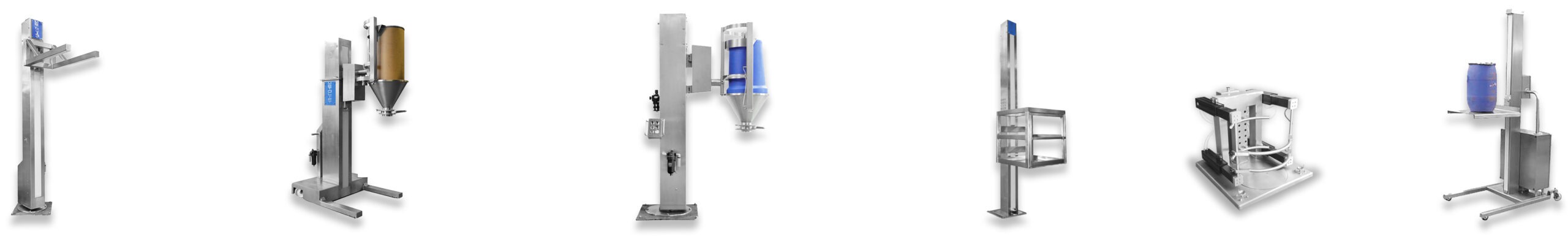

METO Systems produces custom 100-, 300-, and 500-liter bins designed to meet the unique needs of each project. If you’re looking for a tailored bulk handling solution backed by precision engineering and decades of expertise, we’re here to help. Contact us today to discuss your requirements and see how METO can support your operation.

About METO Systems

For over 50 years, METO Systems has been a leading supplier of process and material handling equipment for various industries, including Pharmaceuticals, Fine Chemicals, Nutraceuticals, and Food. Our dedicated staff is here to support you with all your engineering design and installation questions.